Our proven methodology –

from initial design to validating the prototype fixture

- YOUR EXACT SPECIFICATIONS: Our entire design process begins with your application. We take the time to understand your needs in order to craft the right equipment.

- ELECTROMAGNETIC CALCULATION : FEA offers a predictive process superior to trial and error prototyping for obtaining the highest magnetic performance.

- CUSTOM DESIGN & ENGINEERING: Our highly specialized experts design from the ground up. Each fixture is custom engineered to meet the exacting demands of your application.

- THERMAL-ELECTRICAL ANALYSIS: Then we put it to the test. The design must withstand the strength of the magnetic field as well as intense levels of heat and energy.

- PROTOTYPE VERIFICATION: In the final step, the prototype fixture is validated using magnetized samples to ensure its performance.

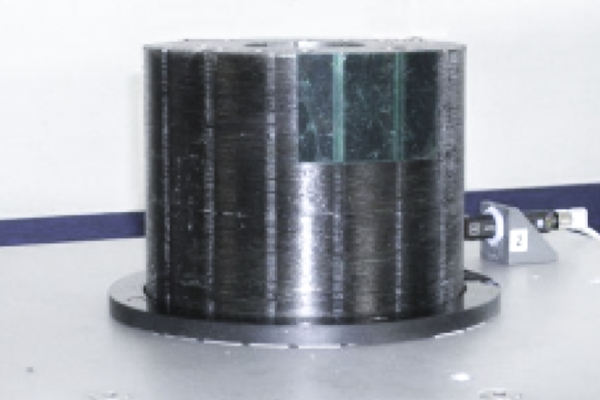

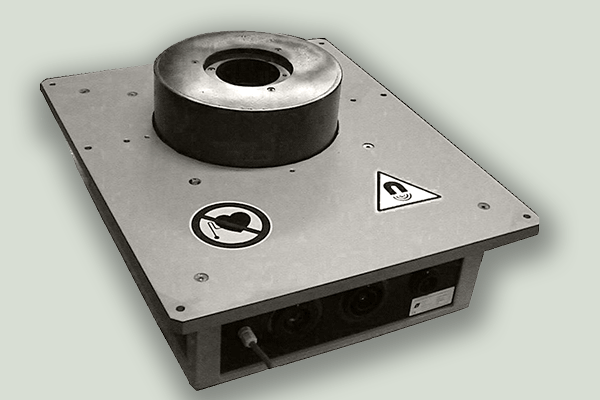

2-Pole Axial Magnetization

This kind of coil is wound by means of round enameled wires, but other cross-section shapes are possible, including: tape, rectangular copper wire, and flat sheet, which is used in the bitter type fixture.

Applications:

- Loudspeakers

- Stepper motors

- Lifters

- Automotive items such as window lift motors, windshield wiper motors, windshield pumps, seat motors, speakers, liquid level indicator

- Household appliances, including washing machines

Key benefits:

- Easier to adapt when a long peak time is required

- Can be used in a dirty environment

Radial Multipolar Halbach Magnetization

The HA radial multipolar fixture has a non-magnetic core, the fixture has the same number of slots as the poles number to be magnetized. Series or parallel conductors are displayed inside these slots. All is embedded in the epoxy resin and encased in an IP30 box.

With this radial multipolar fixture, radial orientation can be achieved in a number of configurations that includes, Halbach, as well as diametric and pure radial.

Our multipolar fixtures consist of a magnetic or non magnetic core, wound by means of enameled wires or machined solid copper or even pipes. They can be either planar or radial. They can be single or multiple traces. Radial orientation can be made in more than one configuration, such as diametric, Halbach, pure radial, can be external for inner drivers or internal for outer drivers. Spatial angular or axial pole displacement can be regular or not. Skewed inductors either step skewed of continuous skewed are available.

Applications:

- Water pumps

- Oil pumps

- Power steering sensors

- Magnetic bearings

- AC brushless motors

Key benefits:

- Low peak time

- Halbach magnetization

- High voltage

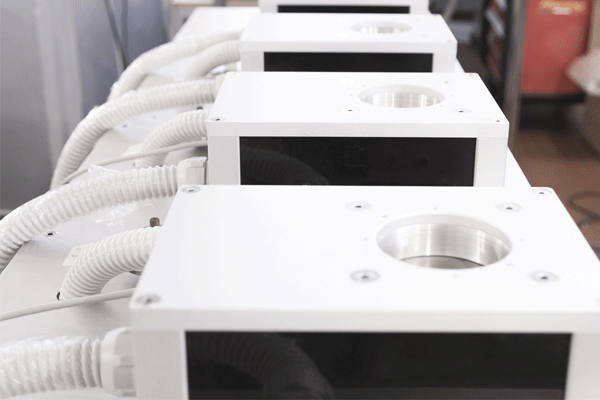

Exterior Radial Multipolar Magnetization

The Exterior HE Radial Multipolar fixture has an iron-laminated core with an equal number of slots and poles to be magnetized. Series or parallel conductors are installed inside these slots. The entire fixture is embedded in the epoxy resin and encased in an IP30 box.

Applications:

- PM inductors

- Claw poles motors

- Wind generators, gearless wind turbines

- Micromotors

- Flywheels (automotive, motorcycle)

- Housings

Key benefits:

- The conductors on the device can be positioned to generate a magnetic field in a desired pattern

- Plenty of space for cooling and insulation material

- Sense coil embedded in the core

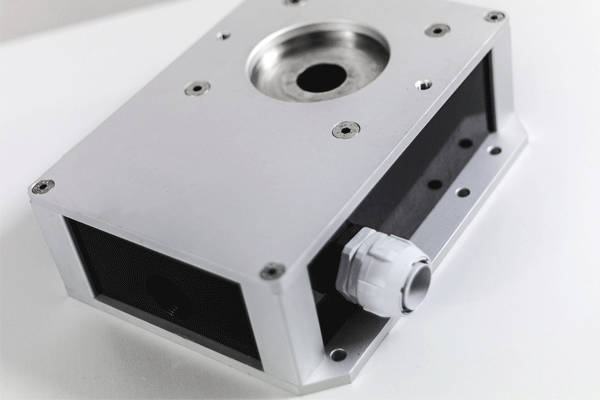

Interior HE Radial Multipolar Magnetizing Fixture

The interior HE radial multipolar fixture has an iron-laminated core with slots in equal number to the poles to be magnetized. Series or parallel conductors are placed inside these slots. The iron-laminated core has a height slightly greater than that of the magnet to be magnetized. It maintains a typical gap from 0.4 to 1mm on the radius, which depends on the diameter of the magnet. The fixture is embedded in epoxy resin and encased in an IP30 box.

Applications:

- Loudspeakers

- Defense applications

- Stators and multipolar flywheels

Key benefits:

- Change the cross-section and number of conductors from project to project

- Minimal space needed for winding heads with our winding technology

- The slots can be built with any type of skewing: step skewed, continuous skewed, zigzag

2-Pole Radial Magnetization

In most cases, the magnetization area is circular or rectangular; but magnetization is often axial. With Split 2-Pole Radial magnetization fixture, two opposing solenoids are used to radially magnetize rings.

Applications:

- Wind generator rotors

- Servomotor rotors

- BLDC rotors

- IPMSM

- SPMSM

- SyRM-PM

Key benefits:

The innovative design allows the coils to be split into two separate half coils, which offers several benefits:

- An increase in the uniformity of the field.

- Radial magnetization of a ring is possible (north interior and south exterior or vice versa) by placing the two semi coils in opposition.

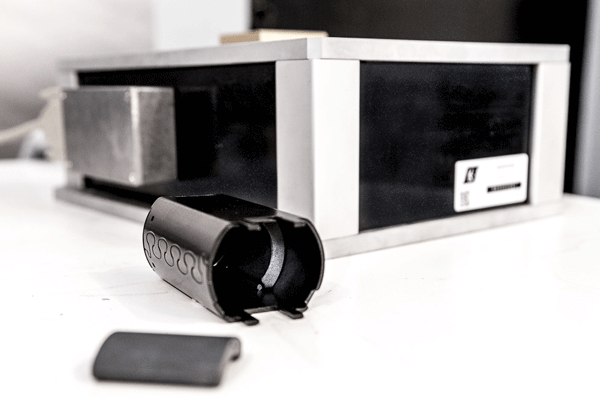

Axial Multipolar Magnetization

An innovative design by Laboratorio Elettrofisico™s R&D team, this patent-pending fixture consists of part of a secondary circuit of a multi-terminal pulse transformer. It’s this secondary circuit that carries the magnetizing current. The state-of-the-art fixture is encased in an IP30 box.

Applications:

- Magnets

- Watches

- Encoders

- Clutches

- Stickers

Key benefits:

- Small pole pitch magnets

- Low voltage

- Low peak time

Skewed Radial Multipolar Magnetization

Get better magnetization on magnet edges, and much more

Designed by Laboratorio Elettrofisico Engineering™s R&D Team, the SAT Multipolar fixture has one single magnetization solid bar for each slot in place of a multiwire slot. The result: better magnetization of the magnet edges.

The SAT Multipolar is composed of two linked circuits, a primary and a secondary. The primary circuit is composed of a few turns of enameled wires; while the secondary circuit is a single solid copper conductor. On the primary, low current is connected to the high voltage side of the capacitor discharging unit. On the secondary, the same power is adapted to a low voltage and an extremely high current. As a result, this fixture requires a reduced amount of insulating material and concentrates higher current density very close to the magnet edges. Both circuits add a magnetization field during the pulse. The fixture is encased in an IP30 box.

Applications:

- Low cogging motors

- Low torque ripple motors

- Power steering motors

- Water pumps

Key benefits:

- High saturation level on magnet edges

- Low insulation required